TOX®-Clinching vs. Spot Welding

Free of charge Test Report

The advantages of clinching predominate

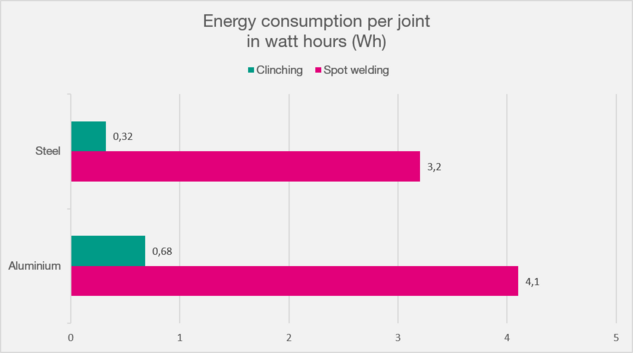

To prove the advantages in energy efficiency, the Laboratory for Materials and Joining Technology at the University of Paderborn was commissioned to carry out an energy consumption measurement for resistance spot welding.

The institute examined a steel-steel and an aluminum-aluminum joint. This was compared with the consumption values of identical clinched joints.

The result: clinching can save 80%-90% of the energy for both material joints. This shows that clinching is the right choice if the CO2 footprint is to be reduced and energy-efficient production is the focus.

Furthermore, clinching eliminates the need for coolants, gas and auxiliary chemicals, which also require costly disposal.

Advantageous dynamic strength without notch effect in the joint - this means: the life of the TOX®-Round Joint lasts much longer than that of a weld point. The TOX®-Joint in customer test results of endurance tests for samples with TOX®-Round Joints and spot welds. The joints were exposed to an initial load of 1 kN and a frequency of approximately 35 Hz. The fatigue life of the joint was measured until failure.

A further, often most important aspect, is the significantly higher dynamic strength of the cold-formed TOX®-Clinch Joint in comparison with spot welding, where the heat brought into the joint changes the material structure which is detrimental for the strength of the welding spot. That’s why dynamically loaded welding spots are inferior to the TOX®-Round Joint with regard to joint strength.

You want to learn more about the advantages of TOX®-Clinching?

|

Contact

US: +1 630 4474600

Contact form

|

|

Cookie Information

We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |