The intelligent servo press with precision mechanics

With TOX®-EdgeUnit, every TOX®-ElectricPowerDrive becomes an intelligent component within the network

- Supply with 24 V

- Internal fieldbus: EtherCAT

- Status LED

- Integrated memory for

- maintenance counter, stroke counter

- drive date, calibration factor

Extend the servo press without additional hardware with the components selected by you by means of comprehensive interfaces on the TOX®-ElectricPowerDrive:

- Additional force input 16 bit ADC (e.g. for external DMS)

- 2 digital inputs / 2 digital outputs

- 2 analog inputs (e.g. for external travel sensor, piezo force sensor)

- Encoder input (e.g. for TTL measuring sensor)

INTEGRATED FORCE SENSOR

- Integrated in the housing as standard (exception: EQe-K 002)

- 4x DMS with <0.5 % measuring accuracy

- Independent of room position, compensated in itself

- Internally connected with the TOX®-EdgeUnit

- Measuring amplifier and 16 bit ADC

to the accessory sensor overview

INTEGRATED POSITION MEASURING

- Resolver integrated on the motor as standard (absolute encoder optional)

- Resolver data are used for closed loop control of the motor

- Calculation of the piston movement based on the resolver data

- Theoretical position measuring up to 1.06 µm

- Distance repeat accuracy of +/- 10 µm

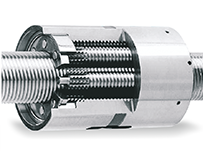

The spindle makes the difference

BALL SCREW

- Compact design and reasonably priced

- Long service life

A typical application example is pressing.

PLANETARY THREADED SPINDLE

- High power density, rigidity and very long service life

- Very small design

Typical application examples are punching, press applications with high joining speeds or press applications in limited installation spaces.

Let us know your requirements - we will dimension the optimum drive system for you. We can optimize your solution with our versions:

- Long holding time of the force

- Reduced cooling time

- Force pulling or punching process

- Increased speed

- And much more

Operating principle of the servo press

Summary of servo press types

The reasonably priced servo drive EQe-K

- Cost efficient

- Stroke length: 150, 300, 450 mm

- Press force: 0.02 – 100 kN

- Ball screw

- 4-point force measuring with high measuring accuracy

- Force repeat accuracy: ≤ +/- 1.0%

- Distance repeat accuracy: +/- 0.01 mm

The flexible servo press for every application: EXe-K

- Now with cleanroom certification! According to ISO 14644-1 applicable up to air purity class 5.

- High power density with low weight

- Stroke length: 150, 300, 450 mm

- Press force: 10 - 200 kN

- Planetary threaded spindle

- Highly accurate 4-point force measuring

- Accuracies: Force: ≤ +/- 0.5%

- Distance repeat accuracy: +/- 0.01 mm

- Low space requirement

- Customized configuration possible

Extremely fast: EXe-F

- Extremely fast and highly dynamic

- Designed for permanent operation

- Planetary threaded spindle

- Highly accurate 4-point force measuring

- Accuracies: Force: ≤ +/- 0.5%

- Distance repeat accuracy: +/- 0.01 mm

- Customized configuration possible

High force with compact dimensions: EXe-L

- Compact and modular design

- Accuracies: Force: ≤ +/- 0.5% (≤ +/- 1% with EPMK 1000)

- Distance repeat accuracy: +/- 0.01 mm

- Planetary threaded spindle

- Force sensors attached to the housing Customized configuration possible