The special machine building company SYMACON GmbH created a complex, robot-supported rotary indexing table assembly and test system with TOX®-ElectricDrive servo drives for large-scale production of bearing housings for the automotive industry.

The medium-sized company SYMACON GmbH, D-39179 Barleben, specialises in automation of manufacturing processes and realises very different systems with robot integration, amongst others for customers from the automotive and automotive supplier industry. The focus is on optimisation of different manufacturing processes to a highly automated and thus highly productive complete solution. Consequently, SYMACON does not see itself "just" as robot system integrator, as it has diverse process know-how on the one hand and proven system solution competence on the other. An impressive example for this is a combined assembly and test system on the basis of a rotary indexing table, which was designed and built for a renowned supplier in the automotive industry. The assembly and test system is characterised by integrating three previously parallel processes into one manufacturing process. This includes component assembly through pressing in components as well as part and assembly testing and finally marking. Handling of the initially tested and approved bearing housings from the outside into the rotary indexing table assembly unit is taken over by a robot. The blanking covers are then pressed into the bearing housing in one workstation in the assembly unit, and the connecting pieces are pressed in in two stations. For this purpose, the connecting pieces and blanking covers are taken from a tray by a second robot and made available in the press-in devices. Following press-in, the first robot takes over the first mounted assembly again and inserts it into the following test and marking cell.

Offered: process know-how! Wanted: precise press force for pressing in!

As already hinted at, SYMACON has highly diverse process know-how, but will also enlist the support of specialists as required. This includes amongst others the company TOX® PRESSOTECHNIK GmbH & Co. KG, D-88250 Weingarten when it comes to joining/clinching and press-in as well as machining or assembly operations that are to be performed by press-in force/path processes. TOX® PRESSOTECHNIK has the technologies as well as the respective press force drives like the pneumohydraulic drive cylinder TOX®-Powerpackage or the mechatronic servo drives TOX®-ElectricDrive. In case of the integrated, robot-supported assembly, test and marking system from SYMACON GmbH, the electromechanical servo drives TOX®-ElectricDrive were selected as drive systems for the press-in operations of the two connecting pieces. When pressing in the blanking covers into the bearing housing, the pneumohydraulic drive cylinder TOX®-Powerpackage is used. The servo drives TOX®-ElectricDrive were used due to the reproducible press-in accuracy, the long-term performance in fully automatic multi-shift operation, the high process safety as well as the option of seamless documentation of the press-in quality. Other aspects of the TOX®-ElectricDrive were simple system integration, low assembly and and installation effort, guaranteed compatibility in service cases, and last but not least the suitable overall solution from one source in connection with the TOX®-Pressing Monitor EPW. Following intensive requirement analysis and consultation with the responsible area manager Burkhard Schmidt, the decision was made in favour of the Electric Power Module of the type EPMK as well as EPMR.

Solution: TOX®-ElectricDrive drives

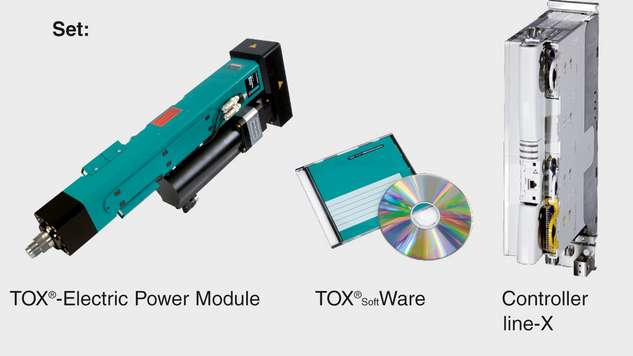

The drives TOX®-ElectricDrive are electromechanical servo drives for reproducible highly accurate joining/clinching and pressing in/injecting. Depending on the version, press forces up to 700 kN can be realised. The electromechanical drives have an integrated control technology and can be coupled with adapted TOX®-Pressing/Process Monitoring Systems for seamless quality documentation. With the pressing monitor EPW, several press stations can be monitored here successively. The EPMK type used once here for pressing in connecting pieces in station 4 is characterised by the parallel arrangement of all components and thus a compact and slim design. The stroke is 100 mm and the working piston speed is 0-300 mm/s. The nominal force is 10 kN, the path repeat accuracy is +/- 0.01 mm. The other servo drive used here in the press-in station 5 is of type EPMR, where components are arranged in parallel as well to form a short and compact unit. Furthermore, this type is equipped with a precision flange. The nominal force is 55 kN here, the total stroke 100 mm, the working piston speed is 1-120 mm/s and the repeat accuracy is +/- 0.01 mm. Every TOX®-ElectricDrive servo drive includes the axis controller line-X with software, cable sets and other accessories for the respectively specific system integration.

EPW monitors press-in procedures and processes

For process monitoring in the three press stations, the multi-channel TOX®-Pressing Monitor EPW is installed. This enables seamless-continuous monitoring of press-in and joining operations, without the need for proven qualified personnel for operation and programming (16 window versions for different monitoring criteria, 64 check routines, up to 10 windows are to be defined per check routine). Furthermore, the control can be realised via a parallel IO port. The scope of delivery also includes the software for parameterising and archiving the data as well as the device configuration. This way SYMACON GmbH got all components and tools relevant for the press-in operations from one source and could focus on its main task as process-oriented system solution partner.