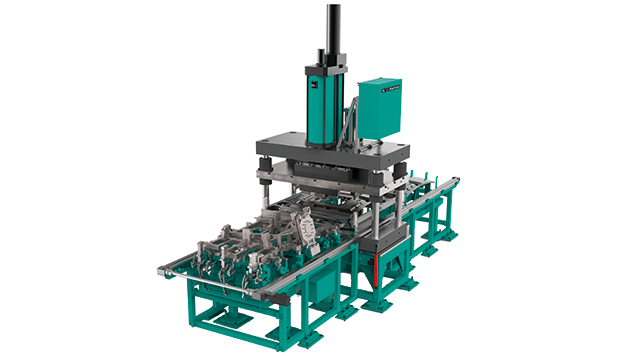

With its components, systems and applications, the technology company TOX® PRESSOTECHNIK GmbH & Co. KG, D-88250 Weingarten can supply customers with partial or complete solutions for special production and assembly processes from one source. In the field of drive technology components, customers can choose from standardized pneumohydraulic, hydraulic or electromechanical drives for the energy-efficient creation of reproducibly precise press forces. The press system business division provides a modular system with a capacity range up to 2,000 kN press force, in which these drive components can be used. In addition to this are TOX®-Controls for press, machine and system controls as well as sensors, software and quality monitoring. This makes the main components for the realization of presses, workstations, robot and machine tongs or system modules and special machines available. Presses, workstations, tongs etc. are used for example for joining, pressing, press-in, separating/punching or assembly operations as well as for clinching and joining metal parts with the TOX®-Sheet Metal Joining Procedures (TOX®-Round Joint to Solid Punch Rivet).

Efficient-economical press, machine and plant engineering

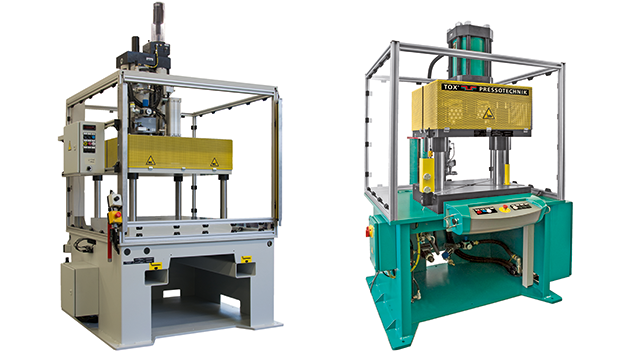

In order to keep costs for production and assembly devices as low as possible and deliver these in a timely manner, TOX® PRESSOTECHNIK has developed a modular press system. The presses with a performance range from 2 to 2,000 kN, including the respectively selected drive system, are based on standardized base frames and accessories, but can always be equipped with customer-specific clinching, press-in, punching tools and with manual to highly automated component feedings.

Standard presses for universal applications

TOX®-FinePress: The bench top presses of this series are designed for press forces between 2 and 57 kN and are available in four designs as toggle presses KF, rack and pinion presses ZF, pneumatic presses PF and pneumatic presses with manual approach PFH. All versions are also available with greater working height and greater throat depth. The bench top presses are characterized by high mechanical precision, a recirculating ball bearing of the ram in the press head, sensitivity in the working process and universally flexible application options.

TOX®-C-Frame bench top presses are available in three designs: MC (cast design with high flexibility due to height-adjustable tool room), MCC (cast compact design for single workstations or several process stations arranged in parallel or in a group) and CEB/CMB (individual, application-related steel/welded design).

The TOX®-C-Frame and C-Bow Presses are available in three designs CEU (steel-welded design with low bending up and continuously height-adjustable dismountable press table), CEC (cast design with large throat depth) and CEJ (flexible modular system for special applications). The design of the TOX®-C-Frame Presses PC is characterized by a welded steel base body with extremely sturdy design and minimum bending up. PC presses are designed for universally flexible applications and can be equipped with very different tool systems and complemented by material flow equipment. The TOX®-2-Column Presses are available as MB and MBG design. Designed as 2-column/2-plate construction with ball screw-guided press plate, they are very compact in relation to the tool mounting area and the load-bearing capacity, and can be equipped as needed for various applications. The TOX®-4-Column Presses also have a ball screw-guided press plate. They are available in the two designs MA and MAG. The solid plate design results in optimum load distribution across the entire tool clamping surface and minimum symmetrical bending up.

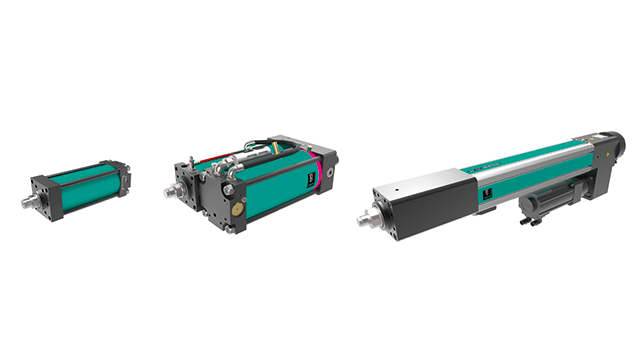

Three drive solutions for optimum press power

While the small presses of the TOX®-FinePress series are either operated manually or pneumatically, for all other TOX®-Presses, either pneumohydraulic, hydraulic or electromechanical drive solutions are possible. Standardized pneumohydraulic drive cylinders of the TOX®-Powerpackage type, TOX®-Hydraulic Cylinders with external pressure intensifier, or electromechanical TOX®-ElectricDrive servo drives are used. This provides customers with optimum equipment for the respectively required production and assembly equipment. The press systems are supplied fully equipped and ready for operation with controls (1-hand start, 2-hand control, 2-hand safety control with PLC, foot pedal control, external impulse control) as well as with safety enclosure according to international standards. Furthermore, TOX® PRESSOTECHNIK designs, builds and supplies tool systems as well as auxiliary and feeding systems for tool handling up to automated, robot-supported production/assembly solutions. Complemented by the TOX®-Pressing Monitor Systems for the quality control of joining, press-in and clinching processes, TOX®-Press Systems and production/assembly solutions become Industry 4.0-capable or integratable.

Own tailor-made configuration of presses

To make selection and procurement of suitable presses easy for customers, an online configurator can be found on the homepage of TOX® PRESSOTECHNIK for the product area TOX®-C-Frame Bench Top Presses. With this configurator, interested parties can compose their “own” ecoLine press system in just four steps. The configurator shows standard C-Frame bench top presses, mounted on a standard base frame. In addition, customers can choose between four press force categories, pneumohydraulic or electromechanical drives, as well as two power stroke versions from the previously defined press force category. The following performance ranges are standardized: Total stroke max. 200 mm, throat depth of the C-Frame Press at 200 mm and press opening at 400 mm. The standard equipment includes a 2-hand safety control, and the interested party can choose from different pressing/process monitoring systems. Once the press system has been configured and the price determined, the quote is requested via the system. The prices of the ecoLine presses configured online are guaranteed! The complete press system is delivered within eight weeks (throughout Europe!).