Thanks to a modular kit system comprising hydraulic, pneumohydraulic and electro-mechanic driving cylinders, tailored solutions for joining, punching, piercing, forming and force fitting are possible.

Today, a great number of sheet metal working, joining and force fitting jobs on pieceparts and subassemblies is done with the help of handheld-, machine mount- and robot tongs. According to the task, most different and above all combined pressforce/distance work flows have to be realized. The necessary drive solutions of conventional type entail considerable expenditures with regard to supply technique and are of comparatively high weight. Therefore industrial manufacturers are looking for solutions which are more simple, reliable and above all easy to handle. These requirements are underlined by standards specially set by automotive industries saying that each work step must be continuously monitored and documented. Now that, for example, the sheet metal machining, joining/clinching and pressing tools are mostly operated in stationary, handheld or robot-guided tongs by heavy, stiff, nonflexible hydraulic cylinders of large dimension, a precise reproducible control of the processes is not possible. Specially as in such cases the process monitoring is also very complicated and allows only a control function but no optimization. For this reason, the specialist for driving techniques and sheet metal joining systems, TOX® PRESSOTECHNIK GmbH & Co. KG, D-88250 Weingarten, offers a modular-compatible kit system containing compact hydraulic, pneumohydraulic, and electromechanic precision driving cylinders. It serves to individually conceive driving techniques for handheld-, machine-mount-, and robot tongs, to build them according to requirements, equip them in a cost-saving way, and operate them finally with high energy-efficiency.

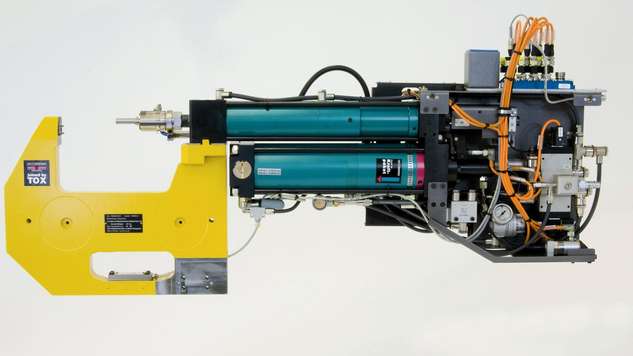

Driving technique for handheld, mini tongs and machine mount tongs

The program reaches from the small, cost-saving standard hydraulic cylinder HZ 40 of compact, closed and simple construction to the standardized pneumohydraulic driving cylinder TOX®-Powerpackage, up to the most precise high-capacity electromechanic servo drive TOX®-ElectricDrive. Including appertaining controls and software as well as process monitoring systems, the modular kit system offers tailored drive solutions reducing the expenses for design, construction and mounting, and finally the cost for the installation of work stations, machines and plants. And also the minimizing of maintenance, service, and operating expenses is granted. Due to the fact that conventional drives are just removed and replaced by TOX®-drives, also the retooling expenditure is within (narrow) limits. TOX®-drive solutions are possible for all handheld-, machine mount-, and robot tongs which in a most flexible way are used for piercing, perforating, joining/clinching, force fitting, riveting, assembling, actuating, beading, stamping, marking, forming/bending as well as clamping and tensioning.

For cost reasons, mini tongs and (stationary) machine-mount tongs are usually equipped with standardized TOX®-hydraulic cylinders of series HZ. Generally, it is possible to equip the hydraulic cylinder HZ with a hydraulic unit for the hydraulic operation of the advance and return stroke. For a pure pneumatic operation the TOX®-Pressure Intensifier ES is available, which converts compressed air in a closed system into hydraulic high pressure. A further drive variant for tongs of this size is the "divided" TOX®-Powerpackage. Named 'KT-system', it consists of a pressure intensifier ES, which is able to supply a single or up to six hydraulic cylinders HZ or pneumohydraulic working parts AT, and offers thus economical solutions. Pressure intensifier and cylinder(s) are connected by hydraulic piping, also provided by TOX®.

Drive technique for (stationary) machine mount and robot tongs

For high-productive operation in series and mass production, the machine mount and robot tongs are alternatively equipped with pure hydraulics i.e. with the TOX®-Hydraulic cylinder RZH, or with the pneumohydraulic TOX®-Powerpackage cylinder type RZK or with Servo-drives TOX®-ElectricDrive type EPMR. The equipment of the hydraulic cylinder RZH is equal to that of the hydraulic cylinder HZ for the handheld-, mini- and machine-mount tongs. For more ambitious jobs, the pneumohydraulic TOX®-Powerpackage is preferred which is characterized by its two-parted total stroke: the air-operated, energy-saving, quick fast approach stroke and the pneumo-hydraulic powerstroke. In addition, there is included free of cost the patented end position damping and the power bypass to prolong service life and to reduce the noise level. If required, also the Powerpackage variant RZK of more compact structural shape and with direct adjustment of the total stroke, or variant RZS of slender execution with external stroke adjustment, can be installed.

With regard to the subject energy-efficiency, the TOX®-Powerpackage driving cylinders take the absolute lead compared to pure hydraulic- or pneumatic cylinders which already consume a lot of energy for the advance stroke, whereas the TOX®-Powerpackage needs it only for the short powerstroke. If the absolute and above all, the reproducible accuracy and integrated process monitoring with documentation are at stake, the servo-drives TOX®-ElectricDrive make their appearance. These are compact electromechanic cylinders with planetary roller threaded spindle and pressure/tensile force sensors. Of modular construction and available with or without mechanic brake, this combination of working pistons with most precise bearing and anti-rotation lock plus planetary roller threaded spindle, secures precise advance stroke/return stroke movements with controlled power progression. This system comprises the controller and the cost-free TOX®softWare, in which the force/travel monitoring is already included. The great additional advantage of the servo drives TOX®-ElectricDrive has to be seen in the fact that due to their mechanic brake, they qualify for the highest safety category, they are also type test approved so that a usage corresponding to "press operation" is permitted.