TOX® PRESSOTECHNIK standardizes CMB press frames

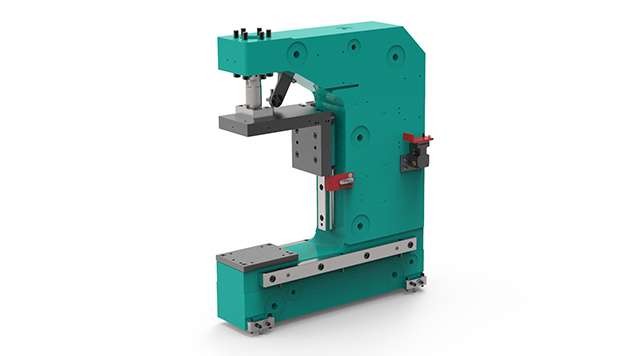

In order to achieve faster delivery times, TOX® PRESSOTECHNIK has standardized its range of CMB press frames. They are used for manual as well as automated processes and are often just part of a production line. Despite their slim design, they are highly torsion-resistant and rigid, and thus ideally suited to forming, straightening, bending, pressing and stamping. Compared to special frames, which must be customized in their design, planning and production, the delivery time of the standard version reduces by around 50 percent.

There are 3 versions of the new CMB frames, and they are designed for press forces between 10 and 320 kilonewton: CMB 050, CMB 160, CMB 320. The throat depth is 200 millimetres, the opening is determined by the tool coupling and measures 430 millimetres. This is sufficient for a maximum stroke of 200 millimetres.

TOX® PRESSOTECHNIK has developed the new standard frames for all relevant TOX® drives for an optimum cost/performance ratio and an installation effort which is as low as possible. The frames can be equipped with the electromechanical servo drive TOX®-ElectricDrive, the pneumohydraulic TOX®-Powerpackage or with the TOX®-Hydraulic Cylinder. Hole patterns on all sides of the CMB frames can be used for pneumatic plates, valves, sensors, restraint devices or for other installations, without the frame needing to be reworked subsequently. TOX® PRESSOTECHNIK supplies fully mounted assemblies with the new press frame coordinated upfront. This also reduces the time needed until commissioning. The new standard frames are available individually or in a package with suitable drive and accessories with immediate effect.